Yogurt, rich in nutrients and delicious in taste, is a classic food loved by consumers of all ages. For businesses looking to enter this lucrative market, a high-quality yogurt making machine line is a necessity. Whether you are a small dairy farm planning to expand or a large food processing company aiming to increase capacity, a complete yogurt line can give you a competitive edge. Get a free quote today! Phone/WhatsApp/WeChat: +86 17837195753

Overview of Foodline Yogurt Making Machine Line

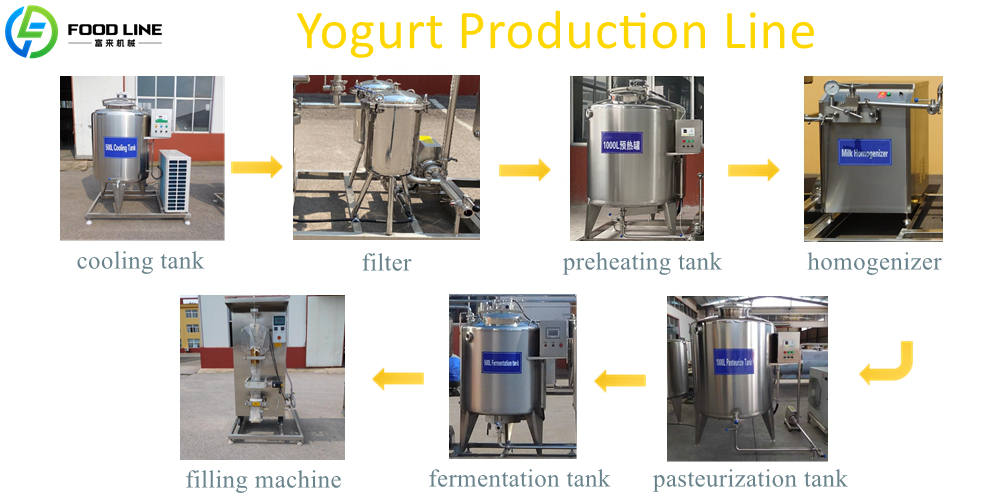

A yogurt making line refers to a series of integrated devices to automate the entire yogurt production process, from raw milk preparation to final packaging. It simplifies every step, ensuring product consistency, efficiency, and compliance with food safety standards. Our yogurt lines are suitable for producing different types of yogurt, including plain yogurt, flavored yogurt, Greek yogurt, frozen yogurt, and probiotic-enriched yogurt, thus flexibly meeting diverse market demands.

Key components of a standard yogurt production line include milk reception equipment, pasteurizers, homogenizers, fermentation tanks, cooling systems, filling machines, and packaging units. Each component works together to transform raw milk into high-quality yogurt with high nutritional value, long shelf life, and that meets consumer expectations. If you need a yogurt making machine line for your business, it’s time to get a free quote! WhatsApp/Tel/WeChat: +86 17837195753

Technical Data of Foodline Yogurt Production System for Sale

| Equipment | Material | Capacity | Parameters |

| Storage tank | SUS304 | 200L | Sheet thickness: 2mm |

| Homogenizer | SUS304 | 300L/H | Power supply: 380v/50hz Output volume: 300L/H Maximum pressure: 25mpa Working pressure: 20mpa Motor power: 3kw Overall dimensions: 755*520*835 |

| Pasteurization tank | SUS304 | 200L | Power of the stirring motor: 0.37kw Stirring speed: 36r/min Electric heating power: 9kw Diameter of the inner tank: 660mm Height of the inner tank: 670mm Inlet and outlet diameters of the material: φ38mm |

| Fermentation tank | SUS304 | 200L | Power of the stirring motor: 0.37kw Stirring speed: 36r/min Electric heating power: 9kw Diameter of the inner tank: 660mm Height of the inner tank: 670mm Inlet and outlet diameters of the material: φ38mm |

Main Features of Our Hot Sale Yogurt Making Machine Line

1. Fully enclosed pipeline process. From raw milk reception and pre-treatment to filling, materials flow through sealed pipelines and tanks. This reduced the risk of human and secondary contamination.

2. Central control system. Key process parameters (such as temperature, time, pressure, flow rate, pH) are automatically controlled and recorded by smart control systems. This allows for consistent batch-to-batch quality and compliance with food safety traceability requirements.

3. Flexible modular design. The yogurt line can be modularly configured and adjusted based on product type (set, stirred, drinking, Greek-style, etc.) and packaging form (cups, bottles, pouches, gable-top cartons, etc.).

4. Stringent hygienic design standards. The yogurt processing line can be equipped with a fully automatic CIP system that performs regular thorough cleaning and sanitization of pipelines, tanks, and other equipment interiors without disassembly.

5. High production efficiency and scalability. Our yogurt making machine line has large processing capacity, ranging from hundreds to thousands of liters per hour. High-speed fillers integrated with automated packaging lines can enhance final output efficiency.

6. Precise control of core process stages. Processes like centrifugation, filtration, and homogenization precisely adjust components such as fat and protein. Use high-efficiency heat exchangers for precise heating to kill pathogens and most spoilage microorganisms and create a clean environment for the starter culture.

Key Processes of High-Capacity Yogurt Manufacturing Line

1. Raw milk reception and filtration. Raw milk is filtered to remove dirt and debris. This guarantees clean raw material for quality yogurt.

2. Pasteurization. Pasteurization kills bacteria via a plate heat exchanger. Milk is then cooled to 43-45°C for fermentation.

3. Homogenization. High-pressure homogenization breaks down fat globules. This prevents cream separation and ensures smooth texture.

4. Fermentation. Yogurt cultures are added, and the mix ferments at 43-45°C for 4-8 hours. Cultures turn lactose to lactic acid, thickening milk into yogurt.

5. Cooling. Yogurt is cooled to 10-15°C to stop fermentation. This preserves probiotics and texture.

6. Flavoring and mixing. Flavors, fruits, or sweeteners are added. A mixer ensures even distribution, avoiding clumps.

7. Filling and packaging. Yogurt is filled into containers, then sealed, labeled, and coded with production dates.

Why Invest in An Automated Yogurt Line

1. Maintain consistent quality and brand image

Automation eliminates human error. From precisely adding starter cultures to precisely controlling temperature, every step follows a pre-set procedure. The final yogurt has a perfectly consistent taste, texture, and acidity in every batch.

2. Achieve Highly Efficient Production

The automated yogurt making machine operates continuously, minimizing human intervention. Machines complete tasks faster and more efficiently, increasing factory capacity and allowing you to confidently handle large orders or expand into new markets.

3. Gain Key Operational Control

Intelligent automation provides you with data and transparency. Integrated sensors monitor key parameters in real time, and the system records every detail. This enables complete traceability of every batch of product, simplifies quality checks, and provides data to further optimize recipes and processes.

FAQs About Our Dairy Processing Line

Q1: What is the average cost of an automatic yogurt maker line?

The cost varies based on production capacity, equipment quality, and features. Choosing a reliable manufacturer can help you get the best value for your investment.

Q2: Can a yogurt making equipment produce other dairy products?

Yes. It can produce other fermented dairy products like kefir, sour cream, and buttermilk with minor adjustments to equipment settings and cultures.

Q3: How to choose the right yogurt making machine line for my business?

Consider your production capacity needs, target products (e.g., plain vs. flavored yogurt), budget, and market goals.

Foodline is Real Manufacturer

We are Henan Foodline Machinery Co., Ltd., a manufacturer headquartered in China specializing in customized food processing equipment. We manufacture machinery with versatility, hygiene, and product quality at its core, helping you transform innovative dairy ideas into marketable products.

Why Choose Our Turnkey Yogurt Project?

- Precision and Stability – Automated control systems ensure products meet your stringent standards for texture and taste.

- Meeting Your Needs – We can configure the appropriate production line based on your product roadmap and factory space.

- Direct Support – As a manufacturer, we provide clear communication, from initial design to after-sales technical support, to help you optimize your operations.

Contact us now for your own discount on the yogurt making machine line:

WhatsApp/Tel/WeChat: +86 17837195753

Email: admin@foodmachfactory.com