A crate washer is a machine for fast, steady, and high-volume cleaning of crates, trays, baskets, and boxes. It replaces manual washing, ensuring each crate is clean, safe, and ready for reuse. If you desire a cleaner production environment and reduced labor costs, this crate washing tunnel is a practical and reliable option. Contact us now for your discount. Phone/WhatsApp/WeChat: +86 17837195753

Technical Parameters of Foodline Crate Washer Machine

| Dimensions (L×W×H) | 4880×1220×1700mm |

| Capacity | 600~1000 /h |

| Total Power | 16 kW |

| Conveying Speed Range | 2~12 m/min, adjustable by frequency converter |

| Number of Water Tanks | 3 in total, operating with a water circulation system |

| Power Requirements | Main drive motor 7 kW Transmission motor 1.5 kW |

| Voltage | 380V AC |

| Cleaning Method | Top, bottom, left, and right spray jet |

| Drain Pipe Diameter | 57mm (Customizable) |

| Water Inlet Pipe Diameter | 32mm (Customizable) |

Our crate cleaning machine can continuously clean, rinse, and disinfect crates. It removes dirt, grease, protein, blood, labels, and other residues. It helps businesses maintain high standards of hygiene and supports smooth daily operations. Need such a powerful machine? Get in touch with us today! WhatsApp/WeChat: +86 17837195753

Technical Features of Industrial Crate Washing Machine

1. Three-stage washing. Alkaline spray, hot water spray, and clean water rinsing. Each has an independent water circulation system to improve cleaning quality.

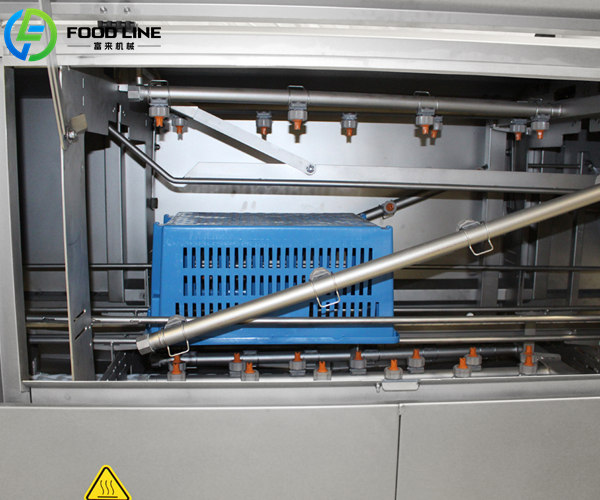

2. High-pressure spray system. Multiple spray heads quickly remove stubborn stains utilizing powerful water flow.

3. Efficient filtration system. Filter screens and sediment tanks intercept impurities, keeping the water clean and extending its lifespan.

4. Hot-water washing capability. The heating module supports cleaning with hot water, thereby improving degreasing and disinfection effects.

5. Adjustable conveyor speed. You can change the belt speed to match your required capacity.

6. Stainless steel structure. Food-grade SS304 makes the machine strong, corrosion-resistant, and easy to maintain.

7. Customizable sizes. Tunnel length, water temperature and pump power can be tailored to your needs.

Application Scenarios of Basket Washing Machine

Our crate washer is suitable for many industries that rely on reusable crates:

– Food processing plants

– Meat, seafood, and poultry processing plants

– Baking and pastry production

– Fruit and vegetable packaging centers

– Beverage and brewery plants

– Dairy plants

– Logistics centers using plastic containers

– Cold storage distribution centers

Who Should Invest in Crate Cleaning System

1. Factory owners who use large quantities of crates daily

2. Production managers looking to improve efficiency

3. Businesses needing to meet stringent hygiene standards

4. Food processing startups looking for cost-effective automation

5. Distribution centers with high crate turnover rates

6. Any business looking to replace manual crate cleaning with a stable, automated solution

If you would like to know if this automatic crate washer is right for your business, please contact us: Phone/WhatsApp/WeChat: +86 17837195753.

Benefits You Gain from Using Crate Washing System

1. Higher hygiene standards. Cleaned crates remain consistently clean, helping to meet food-grade requirements.

2. Lower labor costs. Reduced manual cleaning saves on long-term labor costs.

3. Higher cleaning speed. The machine can process a large number of crates per hour, facilitating smooth production.

4. Lower water and energy consumption. Water recycling and heat recovery systems help reduce operating costs.

5. More consistent product quality. Cleaned crates reduce the risk of cross-contamination, improving the safety of the final product.

6. Longer crate lifespan. Proper cleaning removes dirt without damaging the crates, extending their lifespan.

FAQs About Foodline Crate Washer

1. What sizes of crates can it wash?

We can customize the tunnel width and height according to your crate dimensions.

2. How long does each washing cycle take?

The washing time depends on your conveyor speed settings. You can adjust the speed to meet your desired cleanliness and output.

3. Can I use chemicals or hot water?

Yes. We offer chemical dosing modules and hot water modules.

4. Is it water-saving?

Yes. Water is recycled through a filtration system, reducing water consumption.

5. How do I know the price?

The price depends on the size, capacity, and additional features. Contact us now for the best price: WhatsApp/Tel/WeChat: +86 17837195753.

Partner with Foodline Now

Foodline is a professional food processing equipment manufacturer integrating R&D, production, and sales, providing comprehensive services. We specialize in We offer high-quality cleaning equipment, such as crate washers, commercial dishwasher, sesame cleaning machine, bubble washing machine, etc, to meet your production needs.

Choosing Foodline means you get more than just a machine:

– Expert guidance to help you choose the model best suited to your operations

– Fast delivery and easy installation for immediate use

– Strong after-sales support to ensure your machines always perform at their best

– Durable equipment to protect your investment

Get your quote or free consultation today:

Phone/WhatsApp/WeChat: +86 17837195753

Email: admin@foodmachfactory.com